- WATER TREATMENT AND RECYCLING

- PRELIMINARY TREATMENT

- SECONDARY TREATMENT

- TERTIARY TREATMENT

UNIT 4 – ENVIRONMENTAL DEGRADATION – PART 12

WATER TREATMENT AND RECYCLING

The agenda 21 adopted by the United Nations Conference on Environment and Development, popularly known as the “Earth Summit” of Rio de Janeiro, 1992, identified protection and management of freshwater resources from contamination as one of the priority issues, that has to be urgently dealt with to achieve global environmentally sustainable development.

Water treatment is a process of making water suitable for its application or converting used water into environmentally acceptable water or even drinking water or to its natural state. Thus, water treatment is required before and after depending on the application.

The treatment may include mechanical, physical, biological, and chemical methods and is an integrated comprising of the conventional series of primary and secondary treatment processes, but also includes tertiary treatment and individual treatment of certain streams.

All water treatments involve the removal of Solids, Bacteria, Algae, Plants, Inorganic Compounds, And Organic Compounds. The primary and secondary treatment processes handle most of the nontoxic wastewaters while the water having toxic wastes needs to be pre-treated before adding to this flow.

The treatment process is divided into four stages such as:

- Preliminary treatment

- Primary treatment

- Secondary treatment

- Tertiary treatment

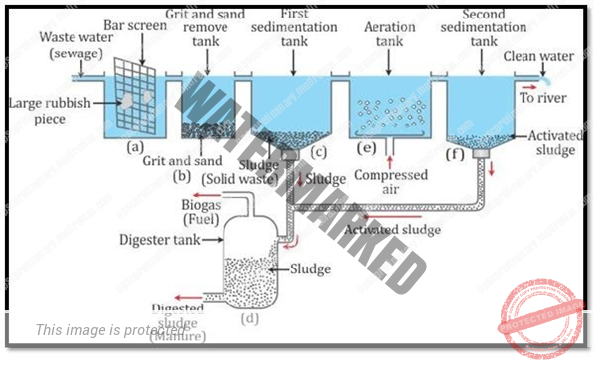

PRELIMINARY TREATMENT: In many wastewaters treatment plants the preliminary treatment is the part of the primary treatment, which includes only the mechanical processes. The pretreatment of the influent involves one or all the following steps depending upon the kind of the wastewater to be treated.

- Screening – Screening removes large solid chunks and objects such as rags, paper, plastics, and metals to prevent damage and clogging of downstream equipment, piping etc.

- Comminutors and Grinders: The processing of coarse solids using comminutors and grinders reduces their size of coarser particles so that they can be removed during downstream treatment operations.

- Grit Removal: Grit includes sand, gravel or other heavy solid materials that are “heavier” (higher specific gravity) than the organic biodegradable solids in the wastewater. The removal of grit prevents unnecessary abrasion and wear of mechanical equipment, grit deposition in pipelines and channels, as well as the accumulation of grit in anaerobic digesters and aeration basins.

- Fat and grease removal: In some larger waste water treatment plants, fat and grease are removed by passing the wastewater through a small tank where mechanical skimmers collect the fat floating on the surface. Air blowers in the base of the tank may also be used to help the recovery of the fat as froth.

Primary Treatment: The equalization tank is followed by neutralization tank where required as streams of different pH partly neutralize each other when mixed. The oils, greases and suspended solids are removed by Floatation, Sedimentation, Filtration, or some-times special equipment is also used to remove grit that gets washed into the wastewater.

The primary treatment prepares the wastewater for the next secondary (biological) treatment. This involves the separation of suspended organic matter (or human waste) from the wastewater.

This is done by putting the wastewater into large settlement tanks for the solids to sink or settle down to the bottom of the tank. The settled solids are called ‘Sludge’. At the bottom of these circular tanks, large scrappers continuously scrape the floor of the tank and push the sludge towards the pump away for further treatment. The rest of the water is then moved to the secondary treatment.

Secondary Treatment: The secondary treatment is the biological degradation of soluble organic compounds that escapes primary treatment. This process is usually done aerobically in an open, aerated vessel or lagoon where the microorganisms degrade this organic matter, which serve as “food” for them. Microorganisms combine this matter with oxygen from the water to yield the energy they need to thrive and multiply.

So, the heavy organic pollution in the river or water bodies can lead to “dead zones” where no fish can be found, and sudden releases of heavy organic loads can lead to dramatic “fish kills”. The water, at this stage, is put into large rectangular tanks. These are called aeration lanes.

Air is pumped into the water to encourage bacteria to break down the organic contaminants of sludge that escaped the sludge scrapping process. The biological process is then followed by additional settling tanks (secondary sedimentation) to remove more of the suspended solids and microorganisms called as activated sludge. A fraction of this sludge is recycled in certain processes, but ultimately the excess sludge along with the sediment solids has to be disposed-off.

Next, the ‘almost’ treated wastewater is passed through a settlement tank, where more sludge is formed at the bottom of the tank from the settling of the bacterial action. Again, the sludge is scraped and collected for treatment. The water at this stage is almost free from harmful substances and chemicals. The water is allowed to flow over a wall where it is filtered through a bed of sand to remove any additional particles. The filtered water is then discharged into the water bodies.

About 85% of the suspended solids and BOD can be removed by a well running plant with secondary treatment. Secondary treatment technologies include the basic activated sludge process, the variants of pond and constructed wetland systems, trickling filters, rotating biological contactors and other forms of treatment which use biological activity to break down organic matter. The existing treatment systems can also be modified so as to broaden the capabilities and performance.

Disinfection: The disinfection typically with chlorine can be the final step before discharge of the effluent. However, some environmental authorities are concerned that chlorine residuals in the effluent can be a problem in their own right and have moved away from this process. Disinfection is frequently built into treatment plant design, but not effectively practiced, because of the high cost of chlorine, or the reduced effectiveness of ultraviolet radiation where the water is not sufficiently clear or free of particles.

Tertiary treatment (to enhance to water quality): The purpose of tertiary treatment is to provide a final treatment stage to raise the effluent quality to the desired level by removing more than 99 per cent of all the impurities from wastewater, producing an effluent of almost drinking-water quality. This advanced treatment can be accomplished by a variety of methods such as coagulation sedimentation, filtration, reverse osmosis, and extending secondary biological treatment to further stabilize oxygen-demanding substances or remove nutrients.

In various combinations, these processes can achieve any degree of pollution control desired. As wastewater is purified to higher and higher degrees by such advanced treatment processes, the treated effluent can then be reused for urban, landscape, and agricultural irrigation, industrial cooling and processing, recreational uses and water recharge, and even indirect and direct augmentation of drinking water supplies.

- Coagulation- Sedimentation Chemical coagulation sedimentation is used to increase the removal of solids from effluent after primary and secondary treatment. The solids heavier than water settle out of wastewater by gravity in the primary and secondary sedimentation tanks but the lighter particles are made to settle down with the addition of specific chemicals, like alum Al2(SO4)3, lime (CaO), or ferric salts of iron (Fe3+ ). With the addition of these chemicals, the smaller particles clump or ‘floc’ together into large masses. The larger masses of particles will settle out in the sedimentation tank reducing their concentration in the final effluent.

- Filtration- Sand filtration, which consists of simply directing the flow of water through a sand bed, is used to remove residual suspended matter. Filtration over activated carbon results in the removal of: non-biodegradable organic compounds, absorbable organic halogens, toxins, dyes Membrane filtration is a process which relies on a liquid being forced through a filter membrane with a high surface area and small pore size to remove bacteria, viruses, pathogens, metals, and suspended solids.

- Reverse osmosis – In the reverse osmosis process, pressure is used to force effluent through a membrane that retains contaminants on one side and allows the clean water to pass to the other side. Reverse osmosis is actually a type of membrane filtration called microfiltration because it is capable of removing much smaller particles including dissolved solids such as salt.

- Nutrient Removal: The nutrients in the form of Nitrogen and Phosphorus present in the treated water causes eutrophication and hence have to be removed. The nitrifying bacteria. are employed for removal of ammonia present in wastewater. These bacteria can biologically convert ammonia to the non-toxic nitrate through a process known as nitrification.

The nitrification process is normally sufficient to remove the toxicity associated with ammonia in the effluent but the product formed nitrate is a nutrient and in excess amounts can contribute to eutrophication in the receiving waters.

In such situations where nitrogen must be completely removed from effluent, an additional biological process can be added to the system to convert the nitrate to nitrogen gas. The conversion of nitrate to nitrogen gas is accomplished by denitrifying bacteria in a process known as DENITRIFICATION.

Effluent with nitrogen in the form of nitrate is placed into a tank devoid of oxygen, where carbon-containing chemicals, such as methanol, are added. In this oxygen-free environment, bacteria use the oxygen attached to the nitrogen in the nitrate form releasing nitrogen gas and it is used for other processes like biogas etc. Therefore in such a manner the waste water can be treated and reused.